- 770-297-7000

- service@murrayplastics.com

- Mon-Thur: 9am-5pm | Fri: 9am-3:30pm

Custom Plastic Injection Molding Company

We are a top-tier custom plastic injection molding company, renowned for our precision, innovation, and quality. Our state-of-the-art facility and experienced experts enable us to create intricate plastic components using advanced molding techniques, consistently delivering excellence to meet diverse client needs.

In-house design and engineering with professional guidance through every step of the process.

Our mold makers have years of experience with custom plastic injection molds and tooling.

Quality-controlled production, experts in a wide variety of capabilities, materials, and sizes.

Murray Plastics loves to work side-by-side with our clients, providing insight, new ideas for a better product, and personable down-to-earth service that can only come from a founder-led United States manufacturer.

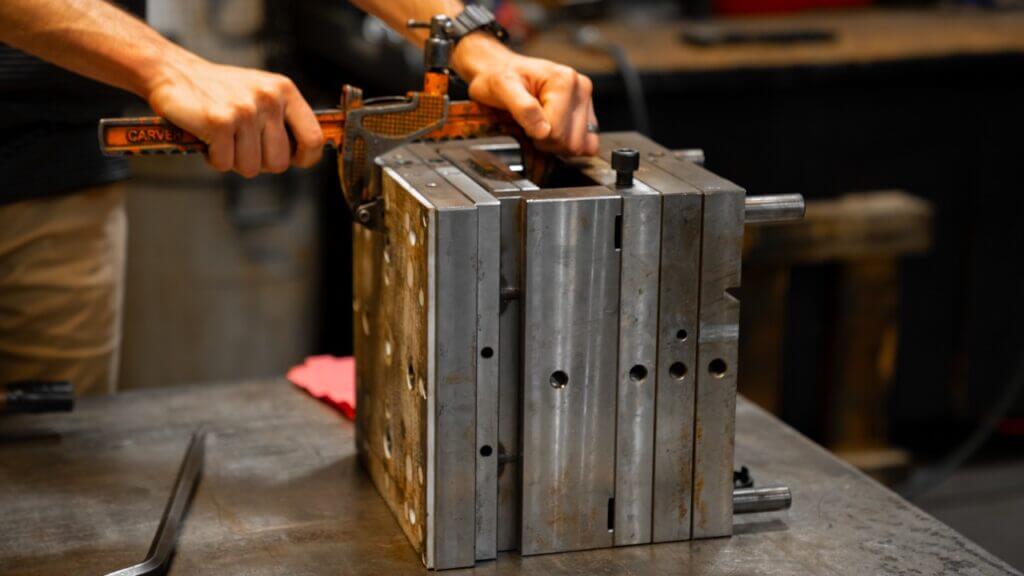

We have over 20 years of experience manufacturing injection molded plastics. Injection molding plastics takes expertise in engineering, design, and mold building to deliver the superior results our customers have come to expect.

We have decades of experience in engineering and building injection molds for plastics. A well-built injection mold is a cornerstone to quality custom injection molded plastic parts.

Our company is engineer-led, so our customers can be confident in the fact that their custom plastic part project is in good hands. Every part we manufacture passes through a rigorous design and engineering process the ensure quality, longevity, and value.

March 8, 2024• Plastic Injection Molding, Plastic part manufacturing• Marl Clevenger