- 770-297-7000

- service@murrayplastics.com

- Mon-Thur: 9am-5pm | Fri: 9am-3:30pm

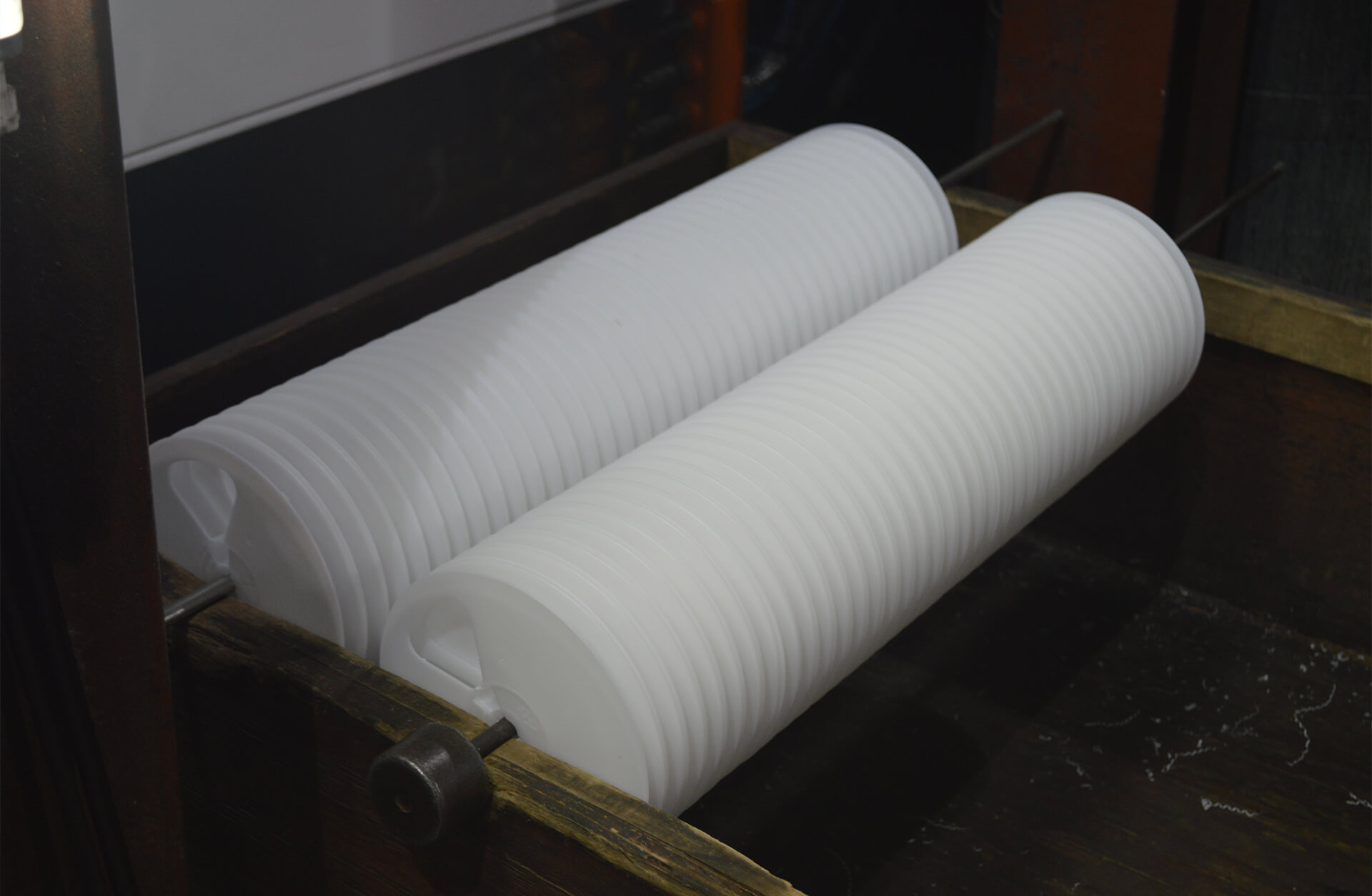

Murray improved the design of the existing surface mount component reel as well as manufactured the new tooling.

Murray Plastics custom-designed and injection molded a polystyrene surface mount component reel for the electronics industry by redesigning the existing component reel and manufacturing new tooling. This process began by determining that there was excessive heat at the center of the original product. After this discovery, we created a new CAD design to figure the ideal gate location and cooling requirements, ran the new tooling to ensure quality, and fabricated molds with P20 steel and 420 stainless steel. For mold repairs and maintenance, we used CNC and EDM machining and an injection molding machine.

The dimensions of the reels can vary from 5 inches to 22 inches in diameter and can weigh from 5 to 40 ounces, with a standard tolerance of +/- 1 millimeter. Using high impact polystyrene in multiple colors and polycarbonate-black, we boast reduced production cycle time, increased quality, and a variety of parts using interchangeable cavities.

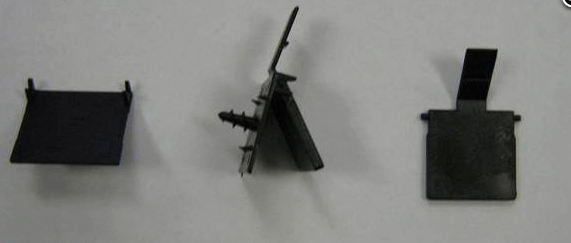

This custom molded RFID switch is used within RFID sensors.

Murray Plastics custom-manufactured copolymer polypropylene RFID sensor switches for the tool vending industry. This process began by developing initial CAD drawings based on our customer’s descriptions and using CNC and EDM machining and an injection molding machine to fabricate new tooling, and run production pieces.

The switch dimensions are 2 inches by 2 inches, with a weight of .13 ounces per part, and a standard tolerance of +/- .0005″, using copolymer polypropylene and P20 steel molds. We place a high priority on customer service, which includes maintaining each customer’s inventory, while performing dimensional, visual, and functional inspections

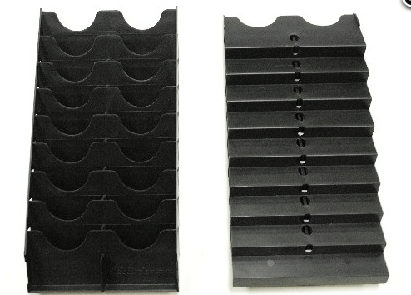

This custom manufactured holder/display is used to display certified collectible coins.

Murray Plastics custom-designs and manufactures recycled polystyrene coin displays for the collectible industry to display certified collectible coins. This process begins by determining the customer’s concept and then creating a rapid prototype for the customer’s evaluation. After all design suggestions are executed, we use CNC and EDM machining and an injection molding machine for mold repairs, maintenance, and running production pieces. The holders are then fabricated using 100% recycled high impact polystyrene.

The dimensions of our coin displays are 10.5 X 5.25 X 1.5 inches and weigh approximately 4.5 ounces, with a standard tolerance of +/- 1 .0005 inches. Using 420 stainless steel and high-impact polystyrene, we boast reduced production cycle time and increased quality. Placing a high priority on customer service, we offer drop shipping to customers and distributors, as well as customer inventory maintenance. Our inspections encompass visual and functional testing.

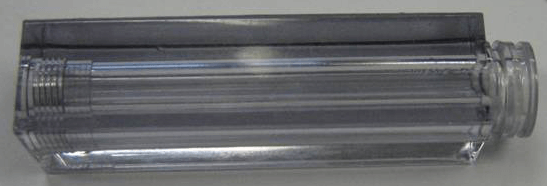

This custom manufactured flow meter tube is used within a liquid measurement application.

Murray Plastics injection molded flow meter tubes for the welding industry, to be used within a liquid measurement application. This process is accomplished by using injection molding. Our mold relies on core pull and features a threaded insert that is manually unscrewed between cycles. The resulting tubes measure 1″ x 1″ x 5 inches, and weigh approximately 3.2 ounces, with a standard tolerance of +/- .0005 inches.

Using clear polycarbonate for the tubes, we boast reduced production cycle time and increased quality. We also place a high priority on customer service, which includes planning and stocking our inventory based on customers’ requests. Our inspections encompass gauge, thread-test, and clarity testing.

This custom molded gauge cover is used within a protective application.

Murray Plastics custom-designed and injection molded yellow ABS gauge covers for the welding industry. After injection molding, we drilled holes to enable easy insertion of screw and bolt hardware. These custom-molded gauge covers are used within a protective application and are based on customer-supplied molds and specifications.

Each of our gauges covers measures 7″ x 7″ x 3 inches, and weighs approximately 3.7 ounces, with a standard tolerance of +/- .0005 inches. We boast reduced production cycle time and increased quality.

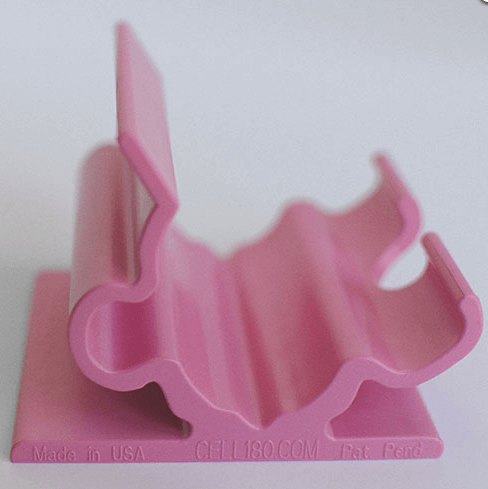

Murray Plastics custom-designed and injection molded multiple colors of phone stands now on sale at Cell180.com. Individual packaging and labeling followed by unitizing is done for the customer and routed to distributors and wholesalers. This product was designed to customer specification by the Murray Plastics design team.